Automatic High Pressure SS Reactor Cleaning System

Automatic High Pressure SS Reactor Cleaning System

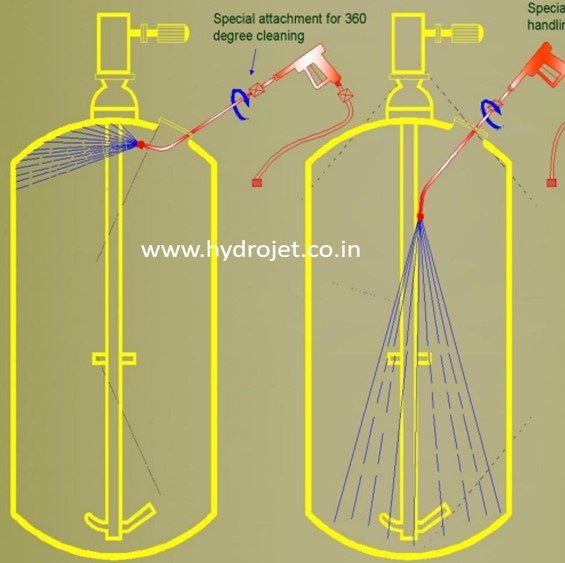

An Automatic High Pressure Stainless Steel (SS) Reactor Cleaning System is a specialized system designed to automatically and efficiently clean reactors used in industrial processes. Typically installed in stainless steel reactors known for their durability and corrosion resistance, such systems are crucial in industries like chemical and pharmaceutical manufacturing, where cleanliness is essential for operational efficiency and product quality.

Tank cleaning is the most essential In the industries. Production of most of Pharmaceutical, Chemicals, petrochemicals, breweries and other process industries, the internal surfaces of vessel cleaning and reactor cleaning at internal surface must be cleaned on a regular basis.

There is usually a build-up of contamination on the reactor walls and on the agitator blade surface, which can be easily cleaned with high pressure tank cleaning equipment. This builds up results in inefficiencies and also the risk of downstream contamination due to debris falling off. Likewise cleaning of jackets of vessels is as much as important as cleaning of reactor tank. If a reactor jacket becomes fouled, a plant can face serious consequences. Over a period of time internal fouling of the jackets in tanks & vessels reduces heat transfer efficiencies, increases reaction times and decreases yield by as much as 15%. In addition, this loss of efficiency can lower a plant’s profitability due to the production of off-quality product, increased maintenance expense and higher capital costs due to shorter equipment service life.

Clean tank and reactor vessels result in faster batch runs, lower plant operating costs and less down time due to downstream contamination. To achieve these results, regular tank cleaning by high pressure water jetting systems is required. Reactor vessel tank cleaning by high pressure hydroblasting equipment improves heat transfer efficiency, resulting in production and efficiency gains and ultimately lowering a plant’s total cost of operation.

Water tank cleaning, ship tank cleaning, storage tank cleaning, silos cleaning, etc….

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |