Manual High Pressure Stainless Steel (SS) Reactor Cleaning System

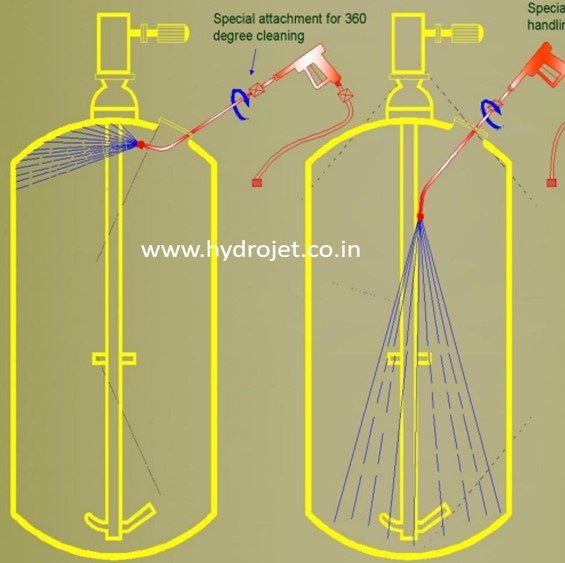

Manual High Pressure SS Reactor Cleaning System

Manual High Pressure Stainless Steel (SS) Reactor Cleaning System is manually with a high-pressure jet system involves several critical steps to ensure thorough and safe operation. Before beginning, it’s essential to isolate the reactor from any process fluids and depressurize it completely. Strict adherence to safety protocols, including wearing appropriate personal protective equipment (PPE) like goggles, gloves, and a face shield, is paramount.

Once prepared, inspect the reactor interior to identify heavily fouled areas. Using a high-pressure water jet system capable of delivering sufficient pressure (typically between 1000 psi to 5000 psi), start cleaning from the top and work downward systematically. Focus the jet on areas with deposits, moving the nozzle back and forth to ensure even coverage and effective removal.

After cleaning, thoroughly rinse the reactor with clean water to remove loosened debris and any cleaning agents used. Inspect the reactor again to ensure all deposits are adequately removed. Once cleaned, dry the reactor using compressed air or allow it to air dry naturally.

Document the cleaning process, noting any observations or issues encountered, and dispose of cleaning agents and materials safely. Regular maintenance and cleaning ensure the Manual High Pressure Stainless Steel (SS) Reactor Cleaning System operates efficiently and prolongs its lifespan.

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |