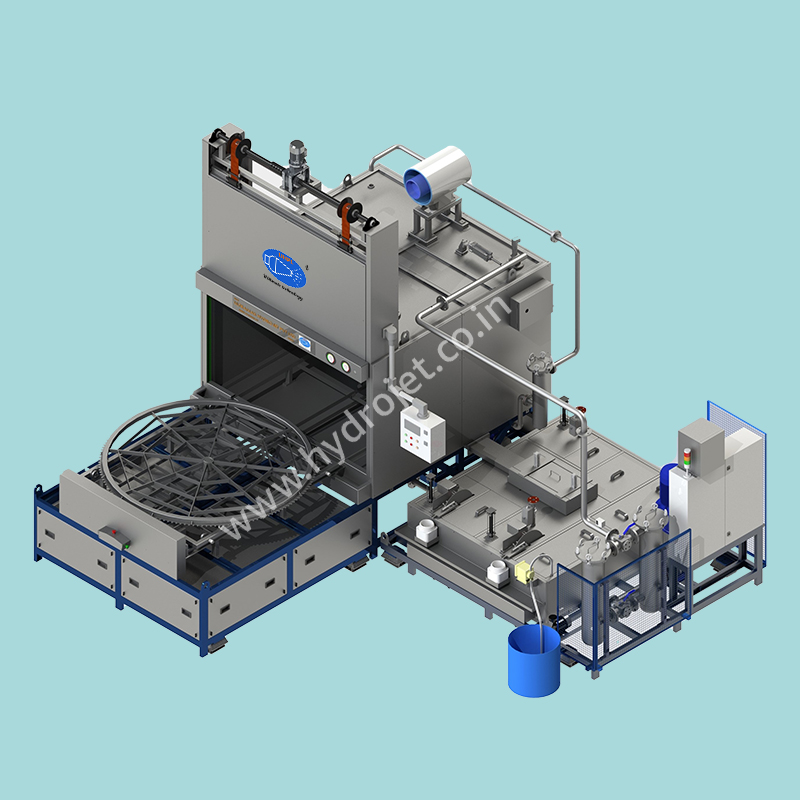

Rail Traction Motor Cleaning Plant

Traction Motor Washing and Drying Plant

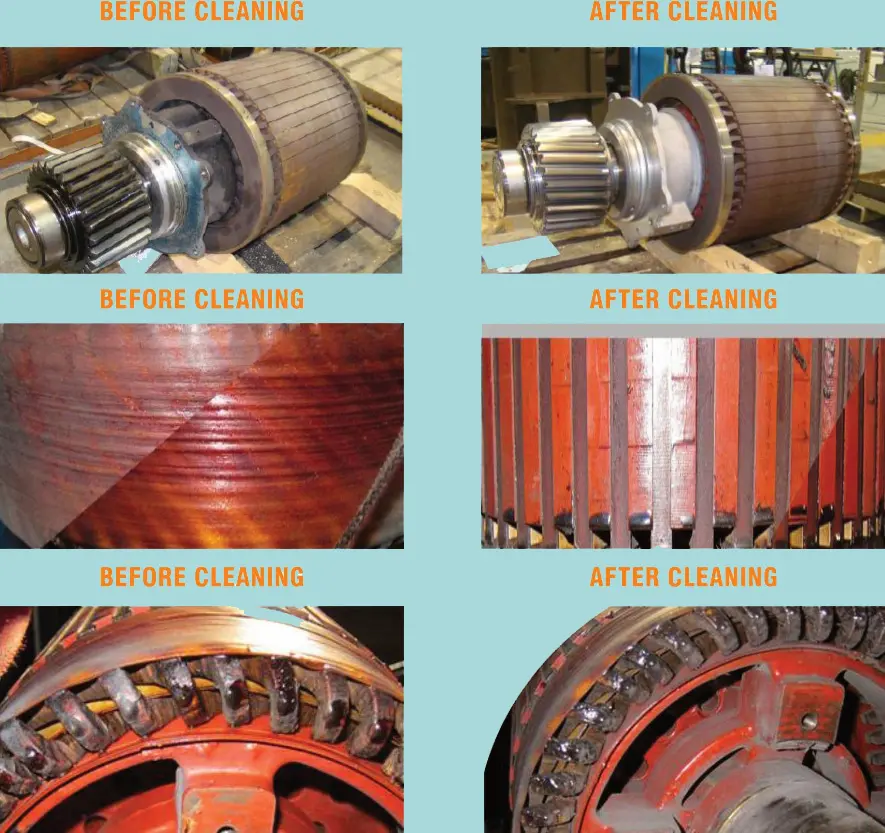

We provide Traction Motor cleaning systems that utilize aqueous-based cleaning technologies, which are environmentally friendly and conserve detergents. Our system is designed for testing and diagnosis purposes, employing a batch-type process that includes pre-cleaning and final cleaning stages. Notably, pre-cleaning and final cleaning are seamlessly executed within a single-stage, closed-loop chamber. Subsequently, the components are transferred to a vacuum drying chamber to ensure thorough drying. This efficient process results in a cycle time of approximately 30 to 45 minutes per batch, ensuring timely and effective cleaning of traction motor components.

- All process such as pre cleaning, Final cleaning& vacuum drying will be done to get the utmost desired cleanliness level

- Automatic complete cleaning of Motor components such as bearings, housings, pinion, suspension parts, etc

- Consistency in the cleaning process by eliminating unnecessary rewinding & detergent residues left at the windings

- Front Loading Batch Type Machine with Auto Door open & close systems

- Reduced running cost & reduction in water consumption & detergents due to recirculation mechanism

- High Productivity with less manual hours

- Reducing the cost of Locomotive Traction Motor during overhauling operation

1 year for OEM components &2 years for workmanship

hydrojetuhpl@gmail.com |

hydrojetuhpl@gmail.com |